A Guide To Oil Cooling Machines

Outline

– Fundamentals and where oil cooling machines fit in modern operations

– Sizing and selection: heat load, oil properties, environments, and energy use

– Installation, controls, and maintenance routines that extend life

– Cost-of-ownership comparisons and supplier evaluation

– Trends, sustainability, and a concise conclusion for decision-makers

1) Fundamentals and Applications: What Oil Cooling Machines Do

Oil cooling machines remove excess heat from lubricating and hydraulic oils so equipment stays within a safe operating band. When oil is too warm, it thins, protective films break down, and components wear faster. When oil is too cool, viscosity spikes, pumps labor, and energy consumption rises. The sweet spot is a narrow corridor, typically defined by the machine builder or process engineer, and staying there can stabilize product quality, reduce downtime, and extend service intervals. Along this journey, you’ll Discover expert insights and recommendations for cooling machines that map to real plant conditions rather than generic catalog assumptions.

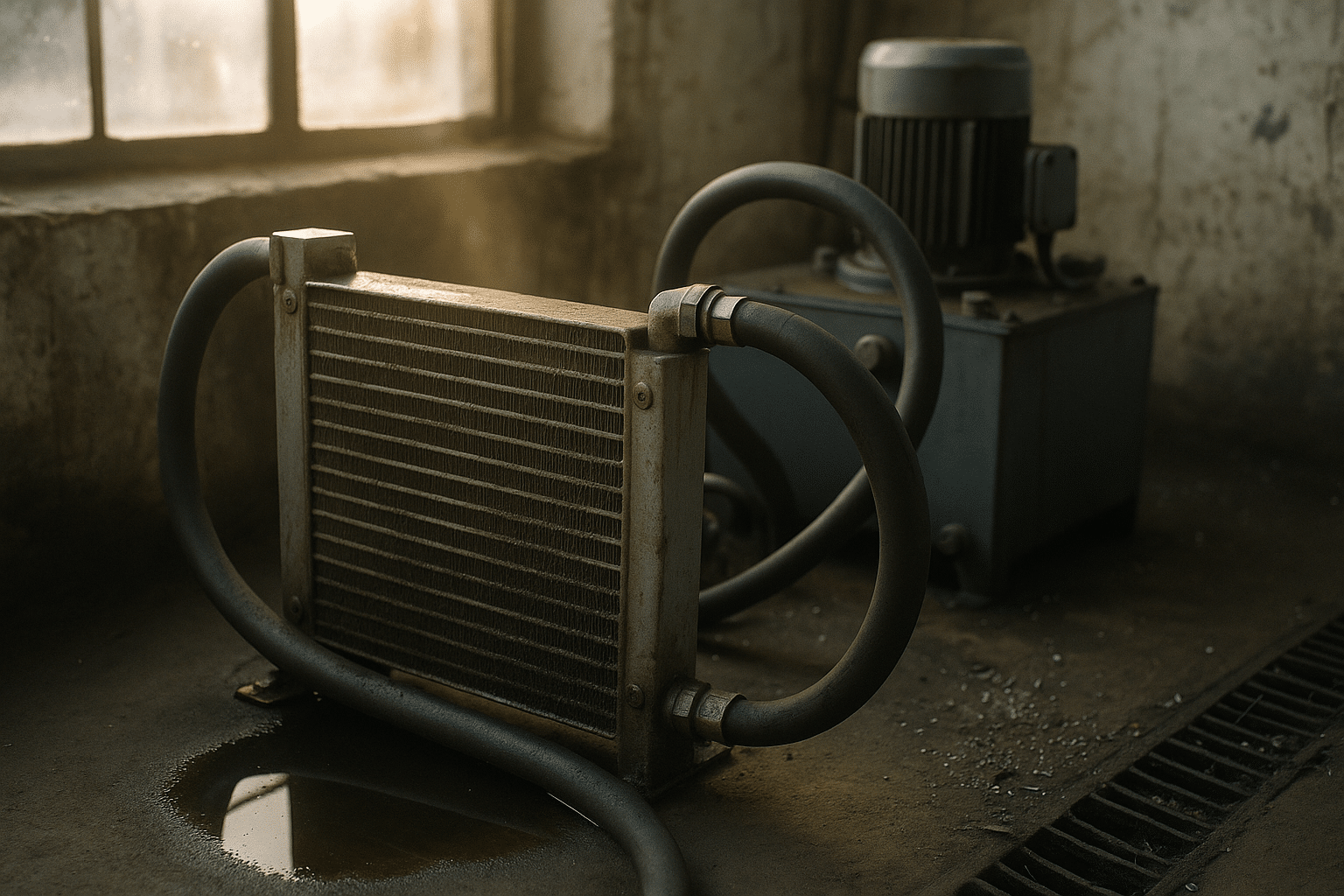

Common families include air-cooled oil coolers, water-cooled shell-and-tube units, brazed-plate heat exchangers integrated with oil circuits, and packaged oil chillers that use a vapor-compression cycle for tighter temperature control. Air-cooled units rely on ambient air to carry heat away through finned coils and fans; they are simple to install, require no water infrastructure, and suit many hydraulics, power packs, and mobile equipment. Water-cooled designs deliver high heat rejection in small footprints and perform steadily regardless of ambient swings, but they need clean, reliable water and attention to scaling. Packaged chillers are selected when precision is critical—think spindle cooling or plastics molding—because they can hold oil within a narrow setpoint.

Typical applications illustrate the range: hydraulic presses, injection molding machines, gearbox lubrication systems, transformers, marine hydraulics, wind turbine pitch systems, and CNC spindles. In each, the oil both lubricates and transports heat away from loaded components. A few practical notes help translate theory into shop-floor realities:

– Match cooler materials to oil chemistry; certain additives can attack seals or brazed joints.

– Check viscosity at operating temperature, not at room conditions, to avoid undersizing pumps and heat exchangers.

– Consider contamination control; a well-placed filter before the cooler protects delicate passages from sludge and varnish.

Ultimately, the “right” machine balances capacity, stability, maintainability, and footprint. Knowing which family aligns with your duty cycle and environment is the first step toward a system that runs smoothly without excess energy or unexpected wear.

2) Sizing and Selection: From Heat Load to Environment

Choosing capacity starts with heat load. Estimate the fraction of input power converted to heat (often 20–40% in hydraulic systems), add process-specific losses, and temper that with duty cycle and ambient conditions. The goal is to achieve a desired oil temperature drop at a realistic flow rate, accounting for viscosity at temperature. While precise calculations use performance curves from manufacturers, a practical workflow is to bound the problem: identify worst-case ambient, peak load, and minimum airflow or cooling water supply.

Here are the Key considerations and factors when evaluating cooling machines options:

– Thermal capacity margin: Aim for a modest buffer so the unit handles summer peaks without oversizing.

– Oil compatibility: Select seal elastomers and gasket materials that tolerate your additive package.

– Pressure drop: Keep within pump capability; excessive restriction raises energy use and shear heating.

– Noise constraints: Fan and pump noise can shape placement and enclosure choices.

– Serviceability: Access to coils, strainers, and filters reduces maintenance time.

– Water quality (if applicable): Hardness and chlorides influence material selection and treatment plans.

Ambient realities matter. Air-cooled units in dusty shops need wider fin spacing or pre-filters; otherwise, fouling eats away at heat transfer. Rooftop installations thrive with abundant airflow but face wind-driven debris and seasonal extremes. Water-cooled systems in recirculating loops benefit from plate-and-frame heat exchangers that can be opened and cleaned, but they require filtration to keep fouling factors manageable. For oil chillers, ensure the condenser can reject heat effectively at local design temperatures; undersized condensers force long compressor runtimes and shorten life.

Energy use is central to total cost of ownership. Variable-speed fans and pumps trim consumption at partial loads, while thermostatic bypass valves prevent overcooling and reduce parasitic losses. In many plants, simple measures—insulating hot runs, routing return oil through the cooler before the reservoir, and specifying high-efficiency fan motors—deliver immediate savings. Finally, document assumptions in a one-page sizing note so future upgrades or audits have a clear reference.

3) Installation, Controls, and Maintenance: Making Performance Repeatable

Even a well-sized cooler disappoints if installed poorly. Mounting orientation affects air purge paths and oil distribution; coils should not trap air pockets, and suction lines should avoid high points where gas accumulates. Flexible connectors reduce vibration transfer to piping, and isolation mounts protect fan frames and pump bases. Place thermometers and pressure gauges on inlet and outlet lines for quick diagnostics. These are not luxuries; they let you see rising pressure drop, slipping thermostats, or underperforming fans before the line goes down. Here you’ll find Professional tips and proven strategies for making decisions about cooling machines that convert vendor datasheets into durable, day-to-day reliability.

Controls deserve equal attention. A simple on/off fan tied to oil temperature works, but staged or variable-speed control narrows temperature swings, cuts noise, and reduces energy draw. Thermostatic bypass valves keep oil above minimum viscosity during cold starts, sparing pumps and bearings. In packaged chillers, look for setpoint deadband adjustments, high-pressure and low-flow safeties, and restart delay timers to protect compressors. For hydraulic reservoirs, locate the cooler on the return line and maintain a slight positive pressure on suction sides to avoid cavitation.

Commissioning is where most early failures are prevented:

– Flush lines to remove welding slag and machining chips; debris quickly fouls fins and plates.

– Verify rotation direction of fans and pumps after electrical hookup.

– Bleed air from high points and check for micro-leaks at flared and threaded joints.

– Validate temperature sensors against a handheld reference to catch calibration drift.

Maintenance intervals should match contamination risk and ambient dust levels. Clean air fins with low-pressure air or a soft brush; high-pressure jets bend fins and reduce effectiveness. Inspect water strains and treat recirculating water to limit scale; a small drop in overall heat transfer coefficient can raise oil temperature noticeably. Track key indicators—pressure drop across the cooler, approach temperature, fan speed percentage—and log them monthly; patterns reveal fouling or control issues long before alarms trip. Done well, these practices turn a critical yet quiet utility into one you barely think about.

4) Cost, Reliability, and Supplier Comparison: Choosing with Confidence

Procurement isn’t only about nameplate kilowatts and price. A better lens is lifecycle value: energy over the unit’s life, planned maintenance, parts accessibility, and downtime risk. Reliability indicators include mean time between serviceable events, coil and exchanger construction methods, fan bearing ratings, and protection features like thermal overloads and flow switches. Documenting your evaluation builds organizational memory and creates fair comparisons across proposals—even when models differ in form factor or control sophistication. The goal is clarity about How to evaluate and compare different cooling machines opportunities without relying on guesswork or vague promises.

Consider building a simple scoring matrix tailored to your process. Weight criteria such as thermal performance at site ambient, noise in dBA at operating speed, pressure drop at target flow, ease of cleaning, spares lead time, and energy consumption at 50% and 80% loads. Add an installation factor for footprint, mounting points, and connection orientation, which can save hours in the field. When proposals arrive, normalize them to a common duty point and ambient, then calculate energy cost using your actual utility rate. Over a five-year horizon, small efficiency differences often outweigh initial savings.

Documentation quality from suppliers is a proxy for support. Look for clear performance curves, wiring diagrams, maintenance procedures with torque specs, and exploded views for spares. When possible, ask for a reference installation comparable in ambient dust, load profile, and oil chemistry. Site visits tell you more than brochures: how do fins look after a year, how noisy is the unit in a real machine hall, and how quickly can a filter be swapped? These practical observations reduce uncertainty and help you select a well-regarded option that meets both engineering and operational goals.

5) Trends, Sustainability, and Conclusion: Where Oil Cooling Is Heading

Efficiency and transparency are reshaping oil cooling. Variable-speed drives on fans and pumps are now widely available, allowing tighter control and lower noise. Microchannel coils and optimized fin geometries improve heat transfer while reducing material mass. In packaged oil chillers, newer control algorithms adapt to load and ambient shifts, preserving setpoint with minimal energy. Connected sensors feed condition-monitoring dashboards, enabling predictive service that targets exactly when fins need cleaning or a pump shows bearing wear. This section brings together the Latest trends and essential information about cooling machines so you can plan upgrades that deliver measurable results.

Sustainability extends beyond kilowatt-hours. Recyclable materials, low-VOC coatings, and drain ports for responsible oil handling are increasingly common. For water-cooled systems, closed loops paired with dry coolers cut water consumption and side-step scaling from once-through setups. Acoustic performance also matters—quieter fans and strategic placement protect worker comfort and compliance. Some operators are adopting biodegradable hydraulic oils; these may require seal and material checks, but they help reduce environmental risk in sensitive locations.

Practical moves you can make now:

– Specify variable-speed fans with temperature-based control to trim energy during light loads.

– Choose wider fin spacing or removable pre-filters in dusty environments to slow fouling.

– Include gauge ports, thermowells, and differential pressure taps in the purchase spec for easy diagnostics.

– Align maintenance with data: set thresholds for approach temperature rise or pressure drop to trigger cleaning.

Conclusion—what this means for you: Oil cooling machines quietly protect expensive assets and throughput. With a clear view of heat load, ambient conditions, controllability, and maintainability, you can select a top-rated design that fits your process and budget. Apply the checklists and comparison steps outlined above, then pilot one unit to validate assumptions before scaling. Small choices—like a smarter fan controller or a cleaner-friendly coil—compound into longer equipment life, fewer stoppages, and a quieter, more efficient operation.